This article was originally written when I had just started this blog and was still figuring out how to structure technical posts.

At that time, however, the technical background discussed here was already closely related to my professional experience in engine design and manufacturing.

I am leaving the original content mostly unchanged, as it reflects my thinking and perspective at that stage.

The reason I initially wrote this in English was that this topic is more relevant to the global motocross and OEM community.

世界中のモトクロスファンを熱狂させた2ストロークのモンスターマシン、CR500R。その心臓部を、現代の技術の粋を集めた2022年式CRF450Rのアルミフレームに搭載する──。これは、単なるエンジンスワップを超えた、ロマン溢れる一大プロジェクトです。通常、この種のコンバートにはフレームの大幅な加工が避けられませんが、なんと今回の挑戦では、驚くほどスマートな方法でエンジンの搭載に成功しました。往年の名機が最新のシャシーで蘇る、その奇跡的なエンジニアリングの第一歩を、詳細な写真とともにお届けします。

この記事を読むとわかること

It can be seen that a 1995YM HONDA CR500 engine can be mounted on a 2021~2023YM HONDA CRF450 frame without cutting the frame!

最新フレームに30年前のENGがそのまま載るってどういうこと!?

What the heck is this—a 30-year-old ENG unit just sitting on the latest frame!?

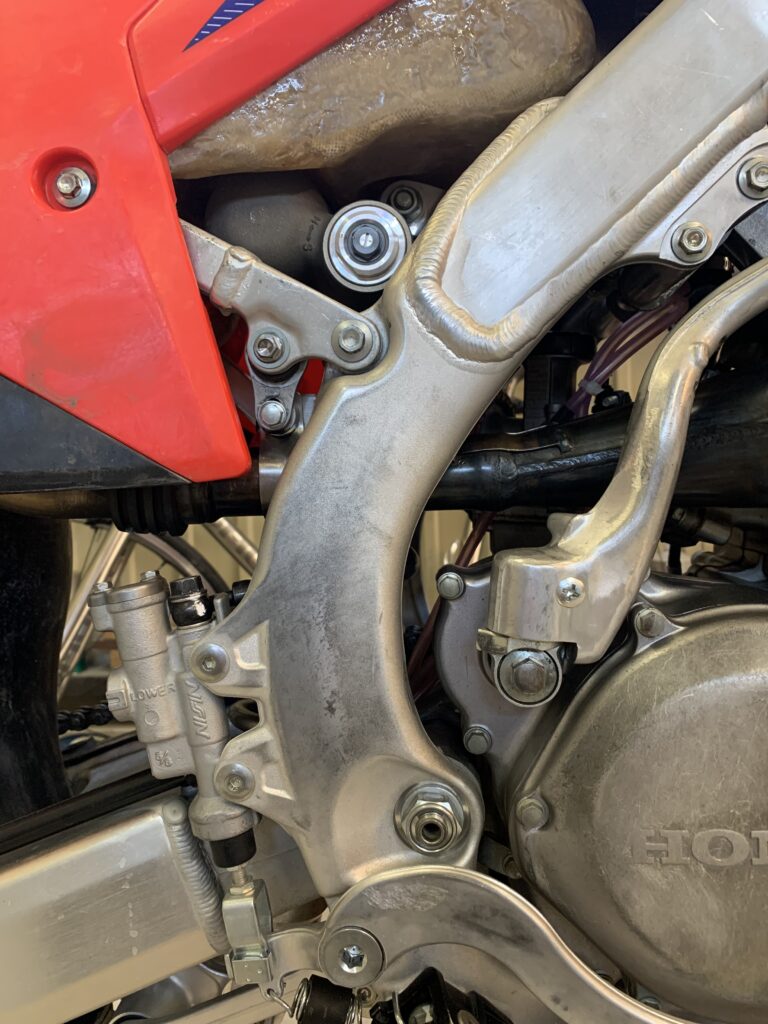

We confirmed that the 1995CR500R engine can be installed on the 2022CRF450 frame without major modifications.

It was an amazing match of frame and engine, as if the frame and engine were designed to accommodate a 30 year old 2-stroke ENG.

👉関連記事 CR500R アルミフレーム搭載 ④ENGの締結マウントについて

スイングアームピボット軸径が同じで長さは3㎜違うだけってどゆこと?

What do you mean the swingarm pivot shaft diameter is the same but the length is only 3mm different?

First of all, regarding the swingarm pivot shaft. I was impressed by the fact that the current 450 and CR500 have the same dimensions of the shaft diameter and its fastening length, and that 30 years ago, they had already found the golden ratio of the dimensions of this part of a machine of this class in terms of power performance.

どうもすでに30年以上前に人間がオフロードで乗るバイクで操れる範囲の最大出力マシンの

ピボット軸幅と軸径の黄金比が見えていたってことですかね???

2022CRF450と1995CR250のスイングアームピボット軸径は同じ。長さは3㎜違い。

キックペダルが干渉せずにくるっと廻るってどういう事?

What do you mean it spins freely without the kick pedal interfering?

After temporarily FIXing the ENG mounting position, I lowered the kick pedal and was impressed by how nicely it rotated without touching the frame pivot.

スイングアーム軸径が同じなので、そのままENGを搭載するとまんま入る笑。

そしてその状態で量産のキックペダルを踏むとメインフレーム鍛造プレートの湾曲に沿って綺麗に

キックペダルが廻るってどういう事???????

量産チャンバーがそのまんま取り付け可能ってどういうこと?

What do you mean the mass production chamber can be installed as-is?

If a commercially available Pro Circuit chamber is installed, it can be assembled without modification. The stock chamber can be assembled by shaving the weld ribs and rewelding them.

Two attached photos. First one. The second photo is of a 2000CR250 in stock condition for reference. The second photo is of a 2000CR250 in OEM condition for reference, with a small modification to the chamber weld ribs.

チャンバーも量産がそのまま付く。

👉関連記事 チャンバー潰れたー!ときのリペア法【初心者必見】これで安心。潰れた2stチャンバーの膨らませ方!

冷却システムについて

About the Cooling System

For the cooling system, the 2022CRF450’s mass-produced radiator was used as is for the FIX. 2 3-way joints were used and routed to maximize cooling using the 2 mass-produced radiators. Although the water hose route is slightly longer and some channel resistance may occur, the overwhelming durability and reliability of the mass-produced radiator is ensured.

Initially, in order to optimize the water hose routing, the radiator was welded and modified to optimize the direction of the JOINT and the JOINT size. However, the radiator is one of the consumable parts that are frequently replaced due to deformation and damage caused by falls of various sizes, and assuming that the vehicle will be maintained as a DIY project, we thought it would be best if the radiator could be used as it is in mass-produced products, so we did not perform any welding modification.

関連記事👉CR500R aluminum frame conversion ③Cooling System Details

操縦安定性について

Regarding Flight Stability

Of course, we would like to improve the vehicle’s maneuverability, but before that, we must first ensure the power output and drivability of the ENG. During the shakedown in the summer, we addressed the initial defects and carb-setting to a certain extent. After that, I have been checking the drivability with my friends and identifying areas for future modification.

Since it seems that the engine has been lightened by about 10Kgf by changing from a 4-cycle engine + exhaust to a 2-cycle engine + chamber, it seems that the suspension needs to be re-set.

ドライバビリティ(出力特性)

Drivability (Output Characteristics)

Intake area has been drastically changed from the mass-produced version. The chamber and silencer have been changed from the mass-produced version. The drivability seems to have been partially changed by these two major changes.

We are currently working to see how much we can get out of the set-up with the mass-produced carburetor.

If you want, please refer to the basic section on carb setting.

Below is a picture of the water hose and electrical harness area after the tank is removed.

It looks good, doesn’t it?

It would be nice if such a bike could be mass-produced.

Continue with (2) air cleaner area and (3) cooling area.

CR500R aluminum frame conversion ② air cleaner box production

今回製作したマウントブラケットやチェーンライン補正値など寸法について

Regarding the dimensions of the mount bracket and chainline correction values produced this time

Please contact me if you need information on the amount of chainline compensation I have calculated on a measured basis or the dimensions of the mounting brackets I have fabricated. I will consider it.

👉関連記事 CR500R アルミフレーム搭載 ④ENGの締結マウントについて

Also, as an option, consider purchasing a mounting bracket, which is a bit more expensive but can be purchased at BVC Offroad.

ちょっと前まで量産ピストンも日本に在庫があったのですが、無くなりまして不自由な世の中です。

ボアスト89X79だと思うのでこのリンクのピストンは量産ボアに使えると思います。

自分用も含めてリンク貼っときます!

かなりオーバーサイズピストンが出回ってるので間違えんようにね。

オーバーサイズピストン買うときは井上ボーリングさんに頼まないかんですけん。

コメント