- What you can learn from this article

- Determination of prerequisites for production

- Started studying specific intake passage routing.

- Heading of Intake passageway (wire routing) Tentative product fabrication

- Relevance of the found pass-through line

- Production of permanent products. Something that can withstand motocross.

- Determination of specifications for connecting tubes

- Determination of air cleaner box specifications

- Connection to rear fender

- Check drivability

What you can learn from this article

The most difficult part of a DIY modified car is the intake area.

Especially the connecting tube (rubber) is a part that cannot be complicatedly shaped by DIY.

This time, we would like to show you one idea or example of how to install a 500 ENG on a recent frame.

Determination of prerequisites for production

製作するにあたり前提条件の決定

The following is my point of view when making this product.

The machine should be able to run MX normally.

If it breaks, I can easily repair it by myself.

The cost must be within my allowance.

Started studying specific intake passage routing.

具体的 取り回しの検討開始

Initially I was going to use the stock connecting tube,

However, the rear suspension sub-tank makes contact and cannot be used as it is.

However, when I looked up the results of this type of modification, I found a case in which the sub-tank of the rear suspension was moved to a different location and fixed in place with a different pairing.

I found a case where the sub-tank of the rear suspension was moved to a different location and fixed in place.

The cost of the rear suspension alone would be over 100,000 yen, which is way over my budget, so I decided to pass.

After a lot of thought, I found an idea for one of the lines (the line for the intake).

Here is a tentative idea.

Heading of Intake passageway (wire routing) Tentative product fabrication

吸気通路取り回し(通線)の見出し 暫定品製作

The pipe material for the prototype is φ60 rain gutters for houses and garages sold at a home improvement center.

It is connected to the carb with a general-purpose intake duct φ63 (inner diameter).

The φ60 rain gutters are sold with flexible bending parts,

It is ideal for deciding on a temporary line in the field.

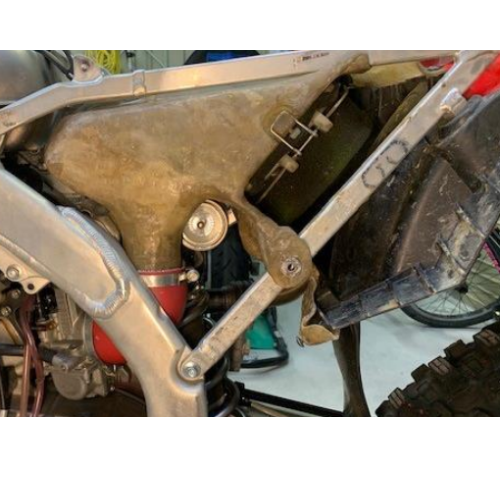

The above photo shows the tentatively completed state.

Relevance of the found pass-through line

見出した通線の妥当性

I had about 2weeks of trouble finding this wire.

I am using a normal carb insulator.

I am using a normal carb insulator.

The left inner frame of the frame is also removed.

The maximum diameter of the rear suspension was also removed.

The rear suspension sub-tank is also eliminated.

The inner diameter is φ60 and can be connected to the factory air cleaner.

Miraculously, we found a line where φ60 can pass through.

The reason why we chose to use a perfect circle instead of an ellipse is because we could use the general-purpose materials that are already available in the world for the manufacturing process.

The reason for sticking to a perfect circle instead of an ellipse is the possibility of using general-purpose materials that are already available in the world for fabrication, thus saving man-hours, cost, and its durability and reliability.

and reliability.

I’m like, “That’s me. I think I can manage with minimal modifications.

I draw drawings every day, but it’s important to have a good match.

Production of permanent products. Something that can withstand motocross.

恒久品の製作 MX走行に耐えられるもの

This is where we start.

(1) How much rubber can be used for the connection with the carburetor?

(2) How to reinforce the gutters and bond them to the stock air cleaner box.

The first is how much rubber can be used for the connection part of the carburetor.

The carburetor is very severe, flying, bouncing, and bumping, running in mud, and being exposed to high-pressure car washes,

The strength, rigidity, vibration, heat resistance, and sealing properties are very important.

We also want to achieve a good balance between drivability and raceability with the 4st450.

Determination of specifications for connecting tubes

コネクティングチューブの仕様決定

(1) We decided to use a commercially available general-purpose silicone hose to determine the specifications of the connecting tube.

Different diameters, different bending angles, and many other inexpensive types are available on the Internet these days.

A 90-degree elbow with a silicone hose inner diameter of φ63 is used here.

This allows the use of rubber to a large extent to absorb vibrations and to coexist with the springs inside the frame and the outermost diameter of the rear suspension,

The elbow can coexist with the spring inside the frame and the outermost diameter of the rear suspension, which are in contact with each other in a subtle way.

Determination of air cleaner box specifications

エアクリーナーボックスの仕様決定

(2) As a conclusion, we decided to fabricate a new air cleaner box entirely out of FRP.

I have recently found an adhesive that can be used to connect the genuine air cleaner box with PP and PE (polypropylene), which is the material of the rain gutters.

However, the adhesives that can be used to connect the genuine air cleaner box and the rain gutters made of PP and PE (polypropylene) are sold these days,

However, it could not be glued together enough to withstand the MX run.

We tried to use FRP as an adhesive to stick them together,

However, PP (PE) and FRP could not be glued together.

Therefore, we applied this in the opposite way,

We made a prototype mass-produced air cleaner BOX modified as a male type (convex type).

FRP is applied on the top and can be easily peeled off after it dries.

The air cleaner box was made by dividing the box into 4 pieces and finally gluing them together with FRP.

Connection to rear fender

リヤフェンダーとの連結

This photo was taken after I had already started riding the car, so it’s not very pretty.

The rear fender area was left as stock.

The sealing performance with the number plate on the L side of the rear fender was secured by using the stock fender,

The primary chamber of the air filter is designed for mass production volume.

We secured all the stock fastening points and added one other point directly above the stock position.

This will not break even if there is a jump short. LOL.

The high-pressure car wash is also used normally.

It’s pretty amazing when you look at it from the back.

It takes a lot of energy to make it as a DIY project.

The back surface is also mass-produced as it is, except for the intake duct shape.

Check drivability

ドライバビリティの確認

The key is the driving, but in terms of engine characteristics, it doesn’t seem to be much different from a production 500.

Is it just that the 500㏄ is so strong to begin with that the throttle is not open enough?

It seems to be a little stronger at low speeds and quicker at high rpm.

However, it is also true that it has reached a speed range and throttle opening that has not been achieved with mass-produced steel frames until now.

I would like to continue to refine the output characteristics of the 2022 frame to match its drivability.

We would like to continue to mature the output characteristics that match the running performance of the 2022 frame.

The FRP frame is unpainted so that the shape can be changed as needed.

We are working on strength measures and intake passage shape optimization while riding.

Please take a look at it for reference.

Followed by cooling system modification results.

2022CR500R aluminum frame conversion ③Cooling System Details

コメント